Write A Scientific Paper (WASP)

..................................................

#UPDATE = 2021-12-25

..................................................

#KEYWORDS = Write, Paper, WASP, ... .

..................................................

# WASP = Write A Scientific Paper.

..................................................

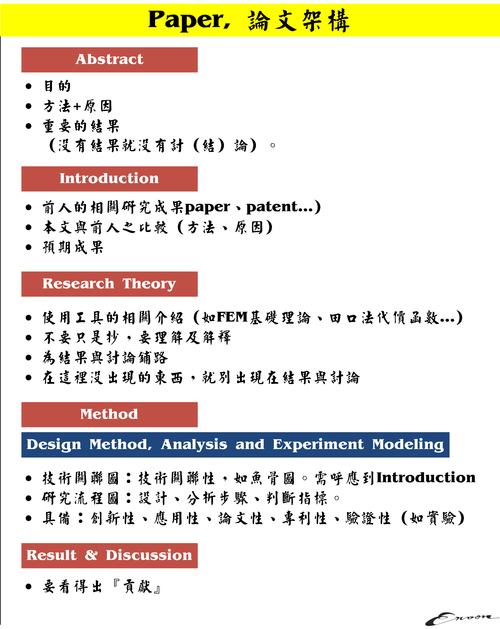

# IMRAD 架構:

Cuschieri 等人 [Cuschieri,2019] 提出 IMRAD 架構來撰寫科學論文。IMRAD架構包括引言(introduction)、方法(method)、結果與討論(results and discussion)。

..........

1. Title 標題:

標題需要具體、精簡、吸睛且直接點出主題;論文標題不包含縮寫,除非論文的重點是指特定的疾病或地區。

..........

2. ABSTRACT 摘要 :

摘要是論文的總結,一般包含:

背景(background)、目標(aim/objective)、方法(method)、結果與討論(results and discussion)等項目。

..........

3. Keywords 關鍵字 :

在摘要之後,提供5到6個關鍵字,作爲索引與搜尋使用,要讓論文能容易被搜尋到。

..........

4. Introduction 引言:

説明技術現況與欠缺的落差,此論文如何填補這技術落差;列出相關聯的參考文獻以避免抄襲問題。

..........

5. Method 研究方法:

告訴讀者此篇論文要做什麽與用什麽方法來進行研究;所述的方法需具備重複性,讓讀者能複製執行此方法。

需包含計算方法、設備、校正用圖表;善用一張圖表勝過用千言萬語來表達複雜的研究流程。

..........

6. Results 研究結果:

結果章節需建立事實、量測與觀察所得的關聯性,有邏輯地説明重要發現,盡可能用文字説明研究成果,可利用圖表説可清楚地讓人理解結果,若有使用到圖表,就要在文章中摘要説明,圖表的標題要能讓人一看就懂的特性,用表格呈現大量資料,用圖來表達趨勢或關聯性。

若非必要,應盡量避免使用有色彩的圖,因爲在投稿時彩頁很昂貴。

..........

7. Discussion - Conclusion 討論與結論:

討論的内容需回答此篇論文在引言章節所提出來的問題或要克服的議題,説明重要發現與先前技術的不同。

..................................................

# REFERENCE

[] Cuschieri, S., Grech, V., & Savona-Ventura, C. (2019). WASP (Write a Scientific Paper): Structuring a scientific paper. Early human development, 128, 114-117.

..................................................